THERA 500

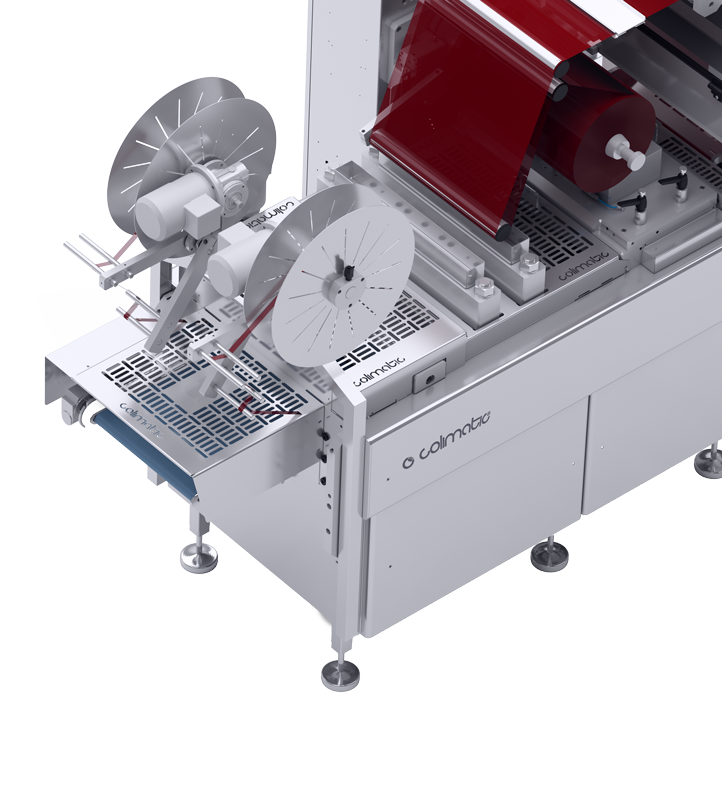

The best Colimatic technology at the service of medium-high production. Full versatility guaranteed by a large loading area and additional space for the integration of accessories after the sealing area.

Available for vaccum MAP, SKIN and SHRINK technologies.

THERA 500: the missing link.

Sustainability

Eco-sustainable materials

• 30% savings on film waste thanks to special vacuum system

• Gear motors with high efficiency

• Cooling circuit with water recycling (no water waste) opt

Technology

• 100% Recyclable paper

• 100% Recyclable mono-materials

• Reduced film thickness min 60 my

features of our products

Build to last

durability, integrity and consistent performance

Compatibility

& synchronizations with a wide variety of devices & accessories

Easy

access for maintenance and service

User friendly

Which allows an easier access to all machine functions, by simplifying the settings, the machine activation and system check.

HYGIENICAL FEATURES

Sloping machine surfaces, TIG continuous welding and motors strategically protected and positioned, Will grant the highest possible hygiene levels!

Extreme energy saving

The configuration with shared DC Bus allows the energy exchange between the axis, reducing the energy wasting caused by the dynamic braking resistances. This will sensibly reduce (down to 40%!) the amount of energy required. (KERS - Kinetic Energy Recovery System).

HINGED CHAMBERS

with folding opening device to allow the fastest format change, cleaning & maintenance operations.

RESISTIVE-TOUCH OPERATOR PANEL

To allow a friendly HMI use in any working condition. The safety system detects hazards, stops the machine and activates the remote assistance service for faster reaction times.

FILM SAVING

up to 30%, Thanks to our unique technology utilizing vacuum and gas injection in sealing phase which reduces the quantity of waste material to only 10 mm of lateral scrap, and only on bottom film, leading to an outstanding single package costs.

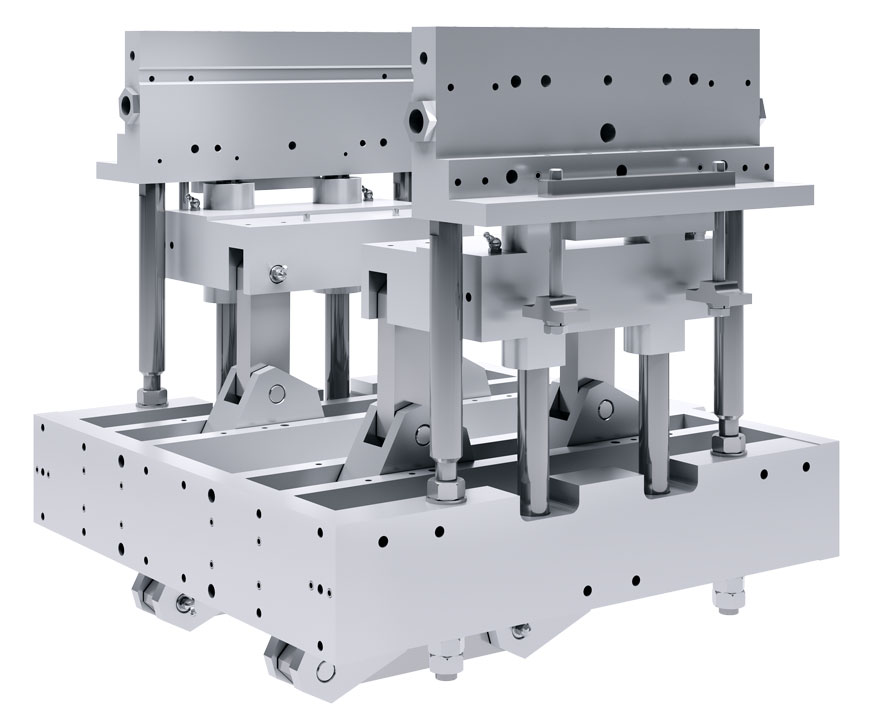

LIFTING MECHANISM

with 4-post lifting unit which consistently guarantees high level of sealing quality due to evenly distribution of the sealing pressure.

Technologies

- Sealing

- Vacuum

- Modified atmosphere (MAP)

- Shrink

- Double chamber automatic

die configuration (FV) - Modified atmosphere (MAP)

- Shrink

components

- Electrical: PLC Siemens

- Pneumatic: FESTO

- Vacuum Pumps: BUSCH

- Control interface: PLC Siemens

performance

- Production: up to 20 cycles/min

- Film material: film thickness up to 800 my

- Top film reel Max diam: 400 mm

- Bottom film reel Max diam: 400 mm

technical features

- Machine length: 7000mm

- Machine width: up to 1100mm

- Machine height: up to 2000mm

- Loading area: 1500mm

- Bottom film width: up to 420mm

- Top film width: up to 400mm

- Max advancing index: up to 400mm

- Pack max depth: up to 120mm