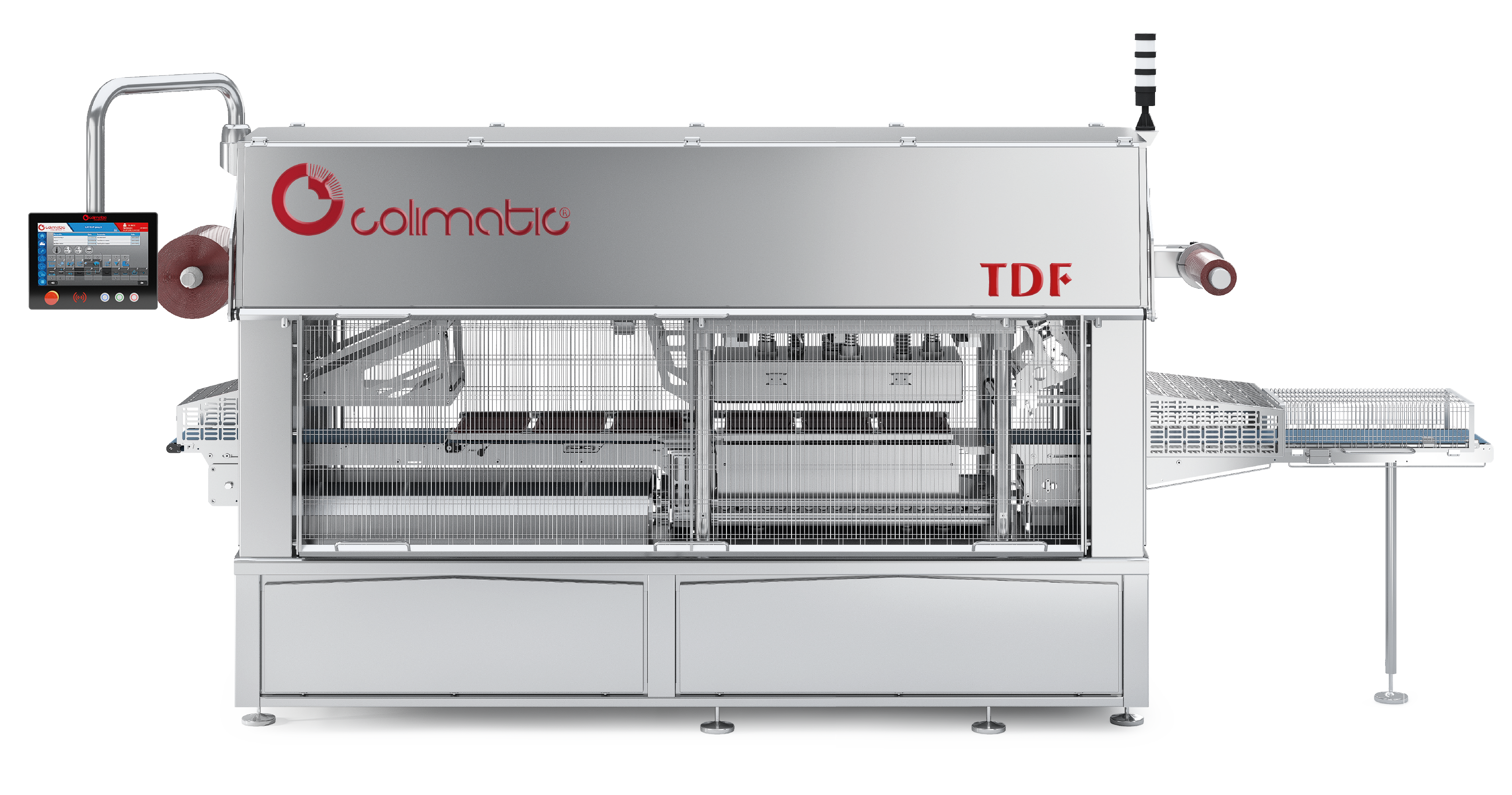

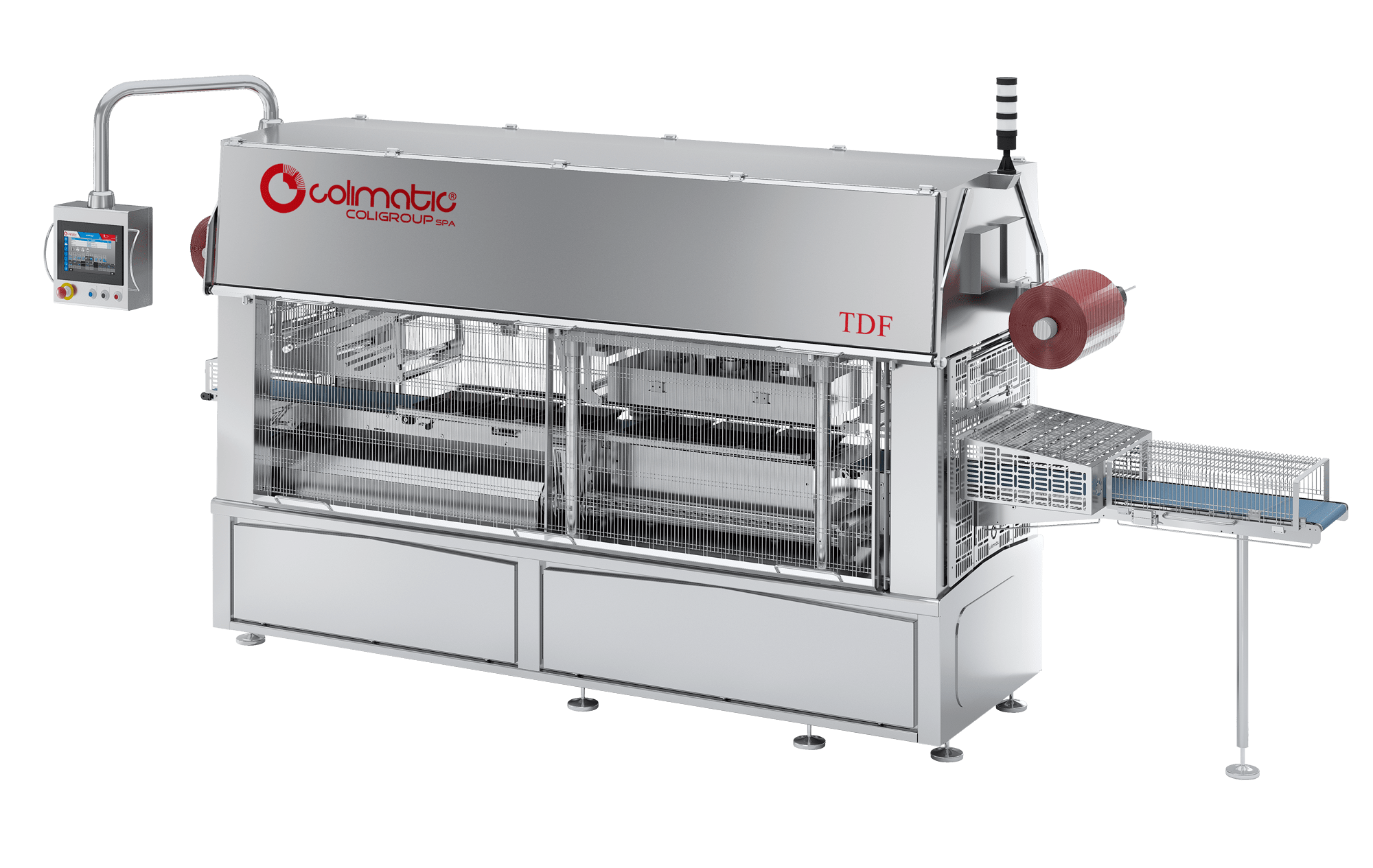

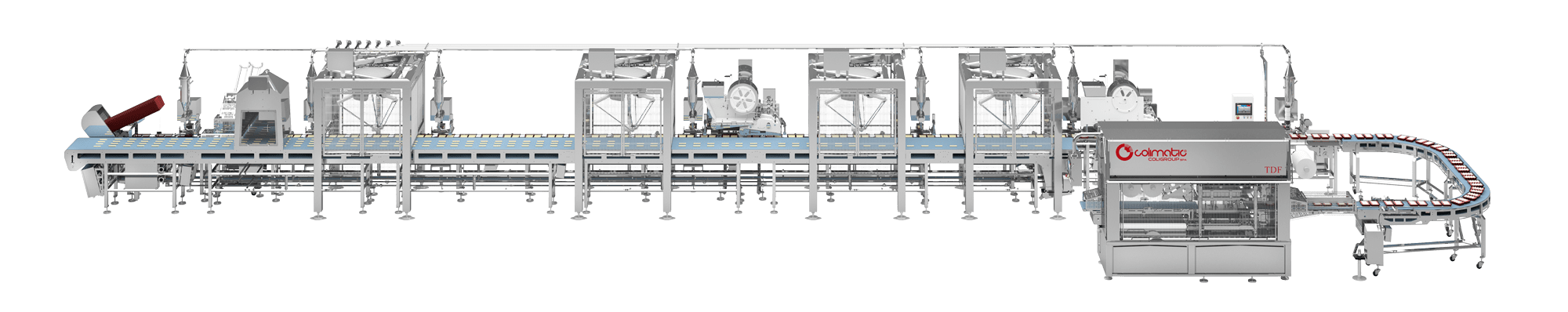

TDF 1650-1900

Brand new and revolutionary fully automatic Traysealer mod. TDF1650 & TDF1900: for the packaging of plastic, cartoboard & aluminium preformed trays, with on-reel plastic films lids, carton lids & reclosing-cap application option. Machine frame completely realized in stainless steel: metal sheets obtained by laser cutting, electrically welded holding elements.

features of our products

User friendly

Which allows an easier access to all machine functions, by simplifying the settings, the machine activation and system check.

SCRAPS REWINDER

Rewinder with pneumatic expansion and increased stroke, to allow the scraps rewinding on both carton or directly on the roll. The group is controlled by clutch with adjustable strength to adapt it to every kind of film. The motor is positioned inside the electrical cabinet.

BRUSHLESS MOTORS

AII machine motion controlled by Brushless motors. These, through an electronic cams connection of the moving components, allow more flexibility in terms of films used and speed control, according to the products to be packed.

PUSHER GROUP

Moved by nr. 2 Servomotors controlled by electronic cam for trays taking, their positioning under the sealing mould and discharge of sealed trays. Their motor is positioned inside the machine cabinet.

SEALING STATION

Servomotor controlled Lifting mechanism of the sealing station, this is managed by the same cam used for the pushers. Sealing strength to be set on the HMI.

INLET BELT

Servomotor controlled positioning system, for trays correct positioning at machine entrance. Made of Stainless steel, it is equipped with fast removal unlock system, to ease cleaning operations: no tools needed for belt handling.

Hygienical features

Sloping machine surfaces, TIG continuous welding and motors strategically protected and positioned, Will grant the highest possible hygiene levels!

Extreme energy saving

The configuration with shared DC Bus allows the energy exchange between the axis, reducing the energy wasting caused by the dynamic braking resistances. This will sensibly reduce (down to 40%!) the amount of energy required. (KERS - Kinetic Energy Recovery System).